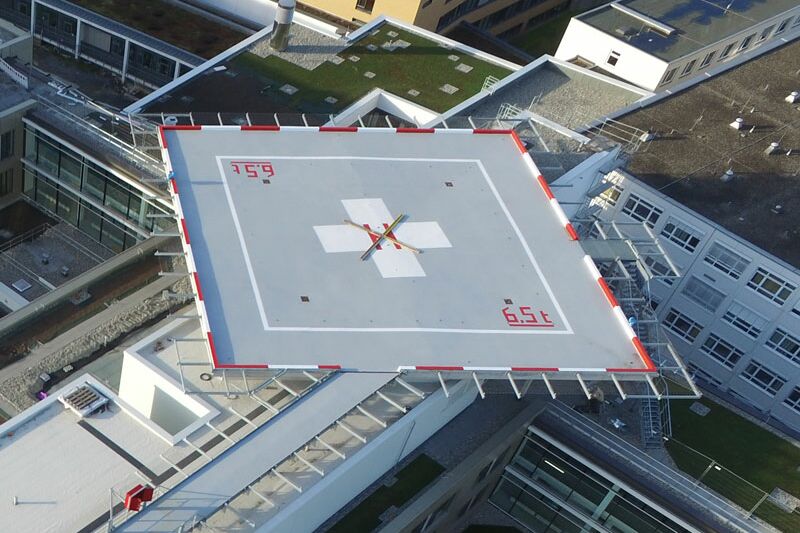

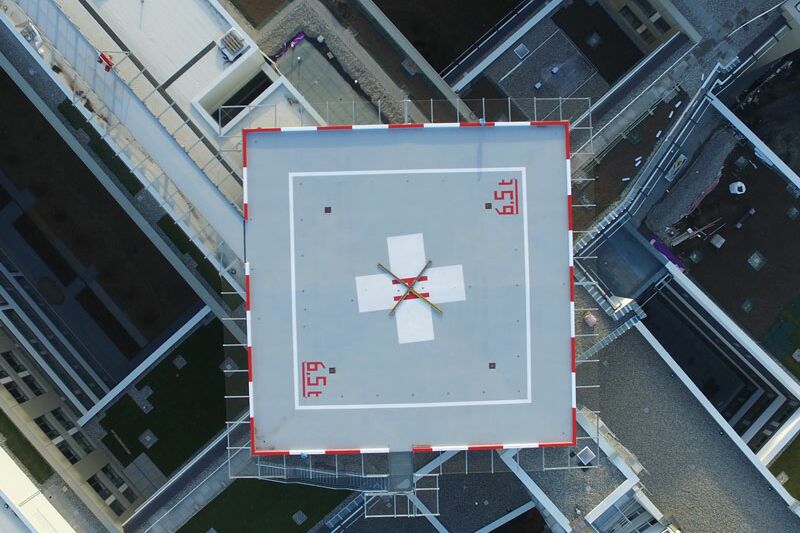

Helipad SLK clinics Heilbronn

You do not simply coat a helipad every day, which is exposed to extreme conditions and contributes to saving people. Pilots have to be in a position to safely land with their patients on board in any weather conditions. The right coating thus helps the rescue-pilots to land despite adverse weather, to keep an overview and to drop off the injured safely.

VIACOR und BETEC win the tender

The SLK clinics in Heilbronn had publically tendered the coating on the hospital’s roof and the company BETEC Beschichtungstechnik GmbH won the bidding. With the consultation and development of a tailor-made coating system of the VIACOR Polymer GmbH BETEC was commissioned. Thus the helipad project could begin.

The implementation

Problem:

- The landing site will be heated for the first time

- The helicopter usually does not land in parallel with both skids and so an enormous point pressure is produced which the coating has to resist

- Temperatures between -20°C to +60°C will occur

Requirements:

The challenge in mixing the fitting system was that the landing site was to be heated for the first time and temperatures between -20°C and +60°C can occur. In addition, an enormous point-pressure is produced as during landing, both skids are usually not set down at the same time. In the case of a coating being too soft, pressure marks would appear which would cause micro fissures in the sealer. These could subsequently be the start of a slow destruction.

The system build-up

Barrier primer:

VIASOL EP-210

This barrier primer without sanding completely seals-in the pores.

Primer:

VIASOL EP-210 lightly sanded witht QS 0,3-0,8 mm

The lightly sanded primer with quartz sand serves the mechanical grip for the subsequent PUR-coating

Wear coat 1:

VIASOL PU-L300V pre-filled with QS 0,1-0,3

The wear layer is cost efficient with a low consumption of binding agents and sands with quartz sand

Wear coat 2:

VIASOL PU-L300V pre-filled with QS 0,1-0,3

The second wear layer is sanded with corundum and a granulation of 1.0 – 2.0 mm

Product properties of VIASOL PU-L300 V:

- Shore D hardness: 60 – 65

- fracture elongation: approx. 30%

- tensile strength: approx. 15 N/mm

Sealer:

VIASOL PU-S650

The sealer is weather- and colour-proof and has a great resistance against acid and lye, lubricant and fuel. The product is easy to clean.

Lining:

PORPLASTIC X990 N

The colour had to be eye-catching and luminous – thus signal red and white were used.

The pressure-resistance arises from the hardness of the sanding materials (corundum). The technical data by far suffices to satisfy the requirements for the application on a helicopter landing pad.