- News

- Parking

- Events

- Industry

- Manufacturing

- Logistics

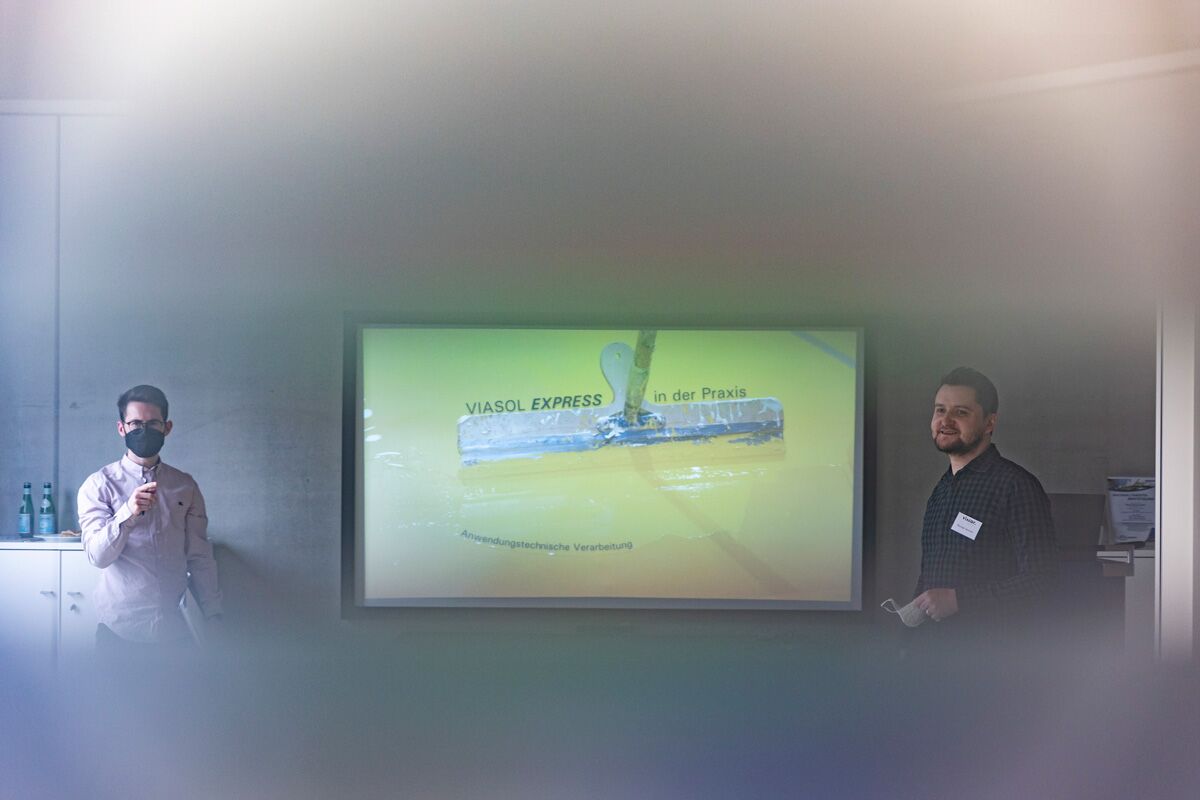

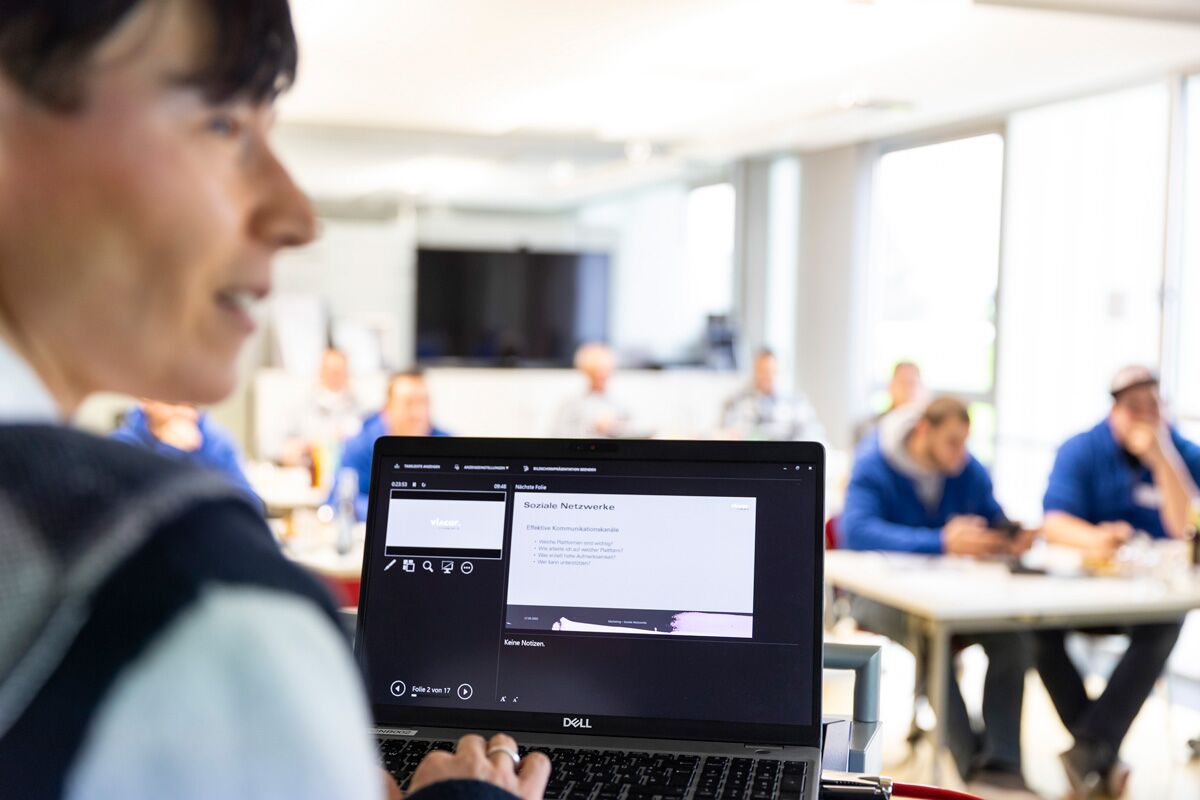

Finally asking, discussing, explaining, answering, presenting and laughing again. It is important for everyone to be able to experience something together again.

After the invitations had been sent, the dates were fully booked within a few days. The number of seminars had to be increased from three to five. In addition, Irene Held created a waiting list for further registrations. We were literally overrun.

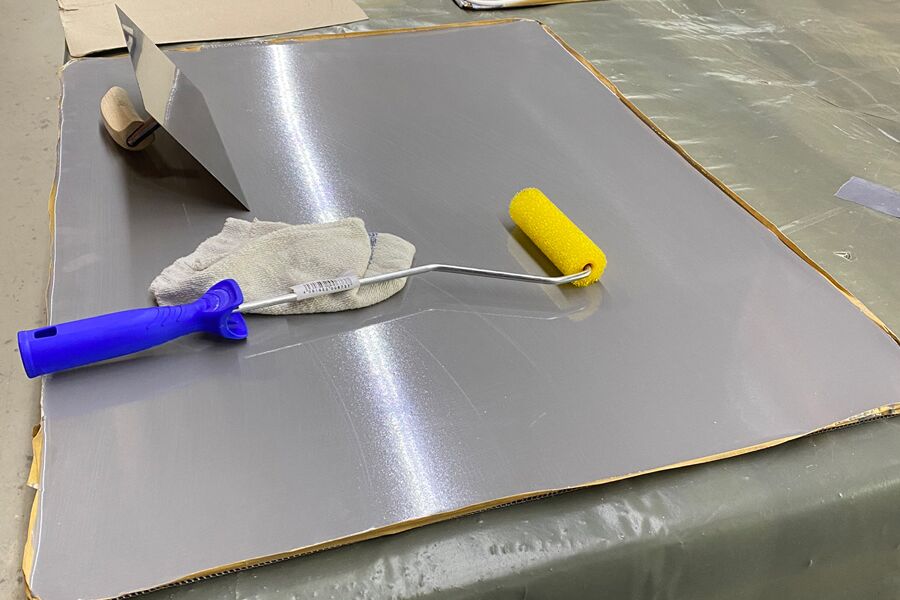

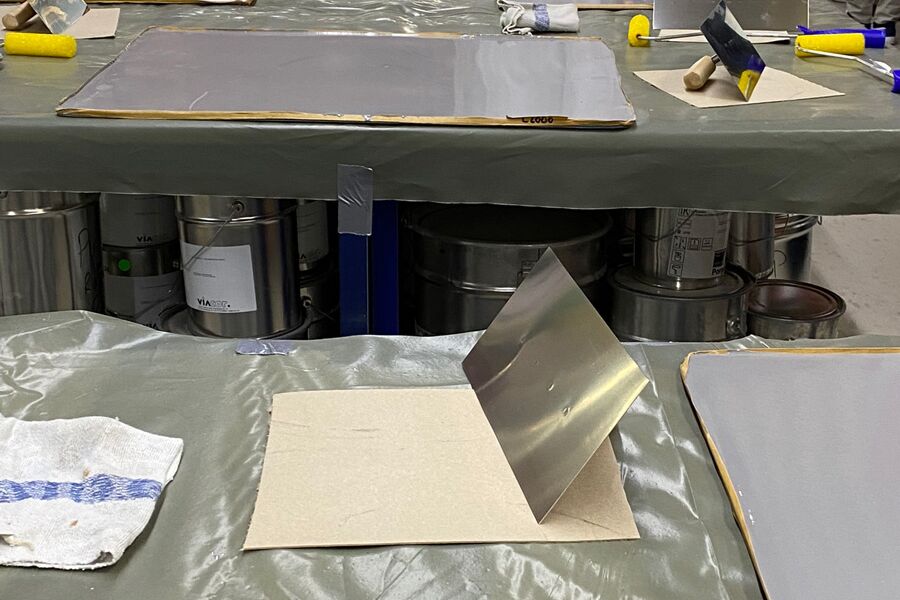

The following topics on innovative floor coatings were presented in theory and practice:

- VIASOL EXPRESS Systems

- The fast, economical systems that save time and personnel costs

- VIASOL UNIFLEX cuisine SR

- The perfect flooring system for industrial kitchens

- VIASOL DECK rapid M

- The innovative surface protection systems for parking areas