- Industry

- Manufacturing

- Logistics

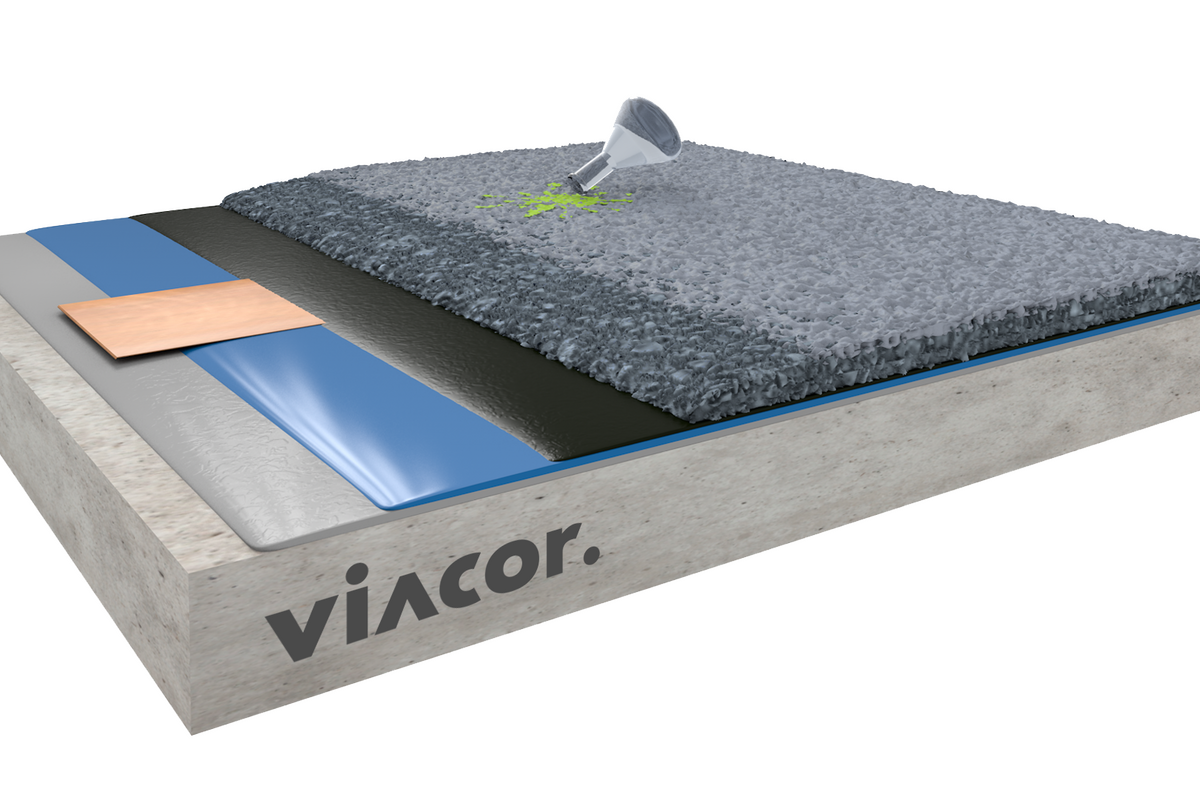

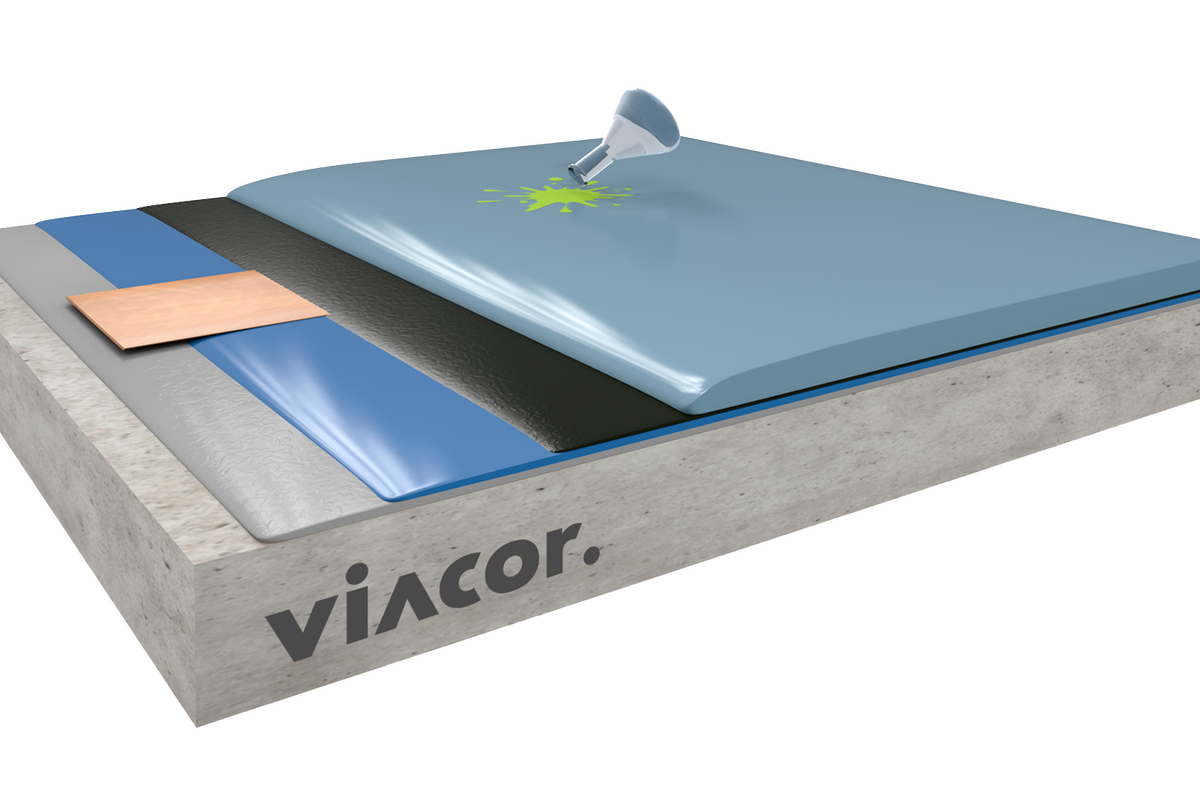

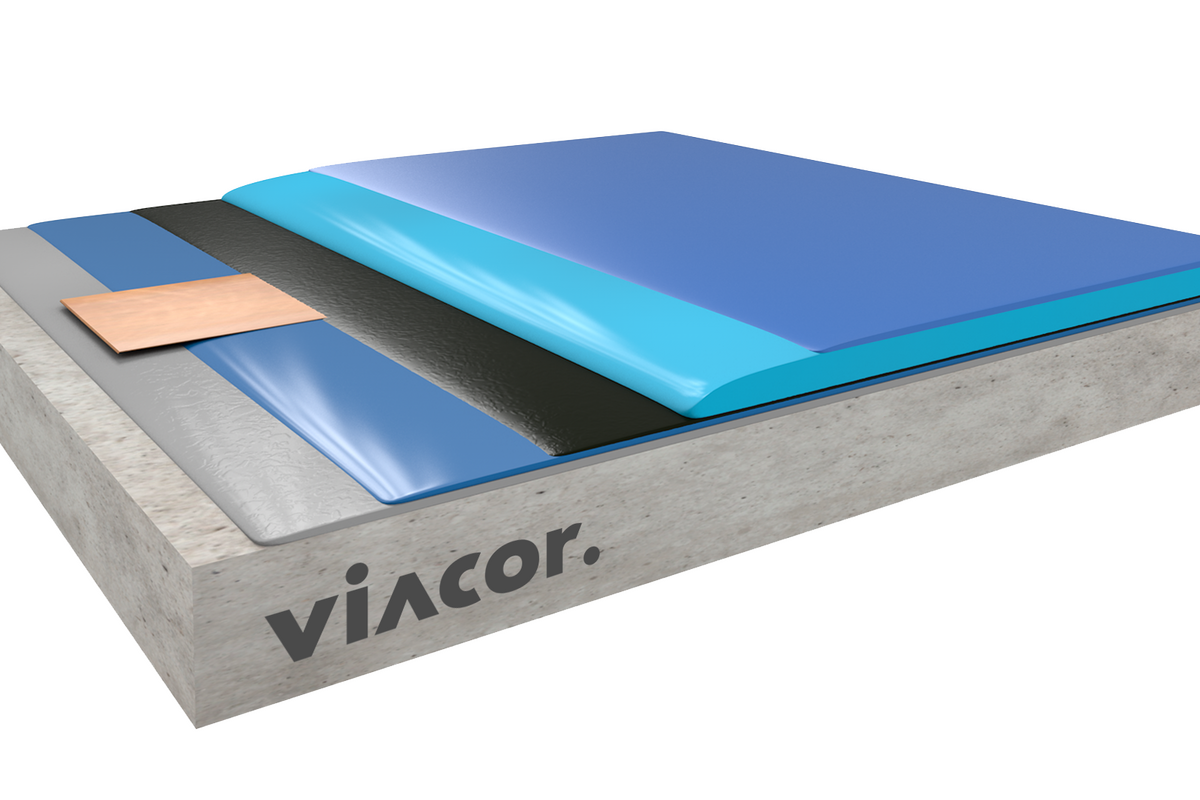

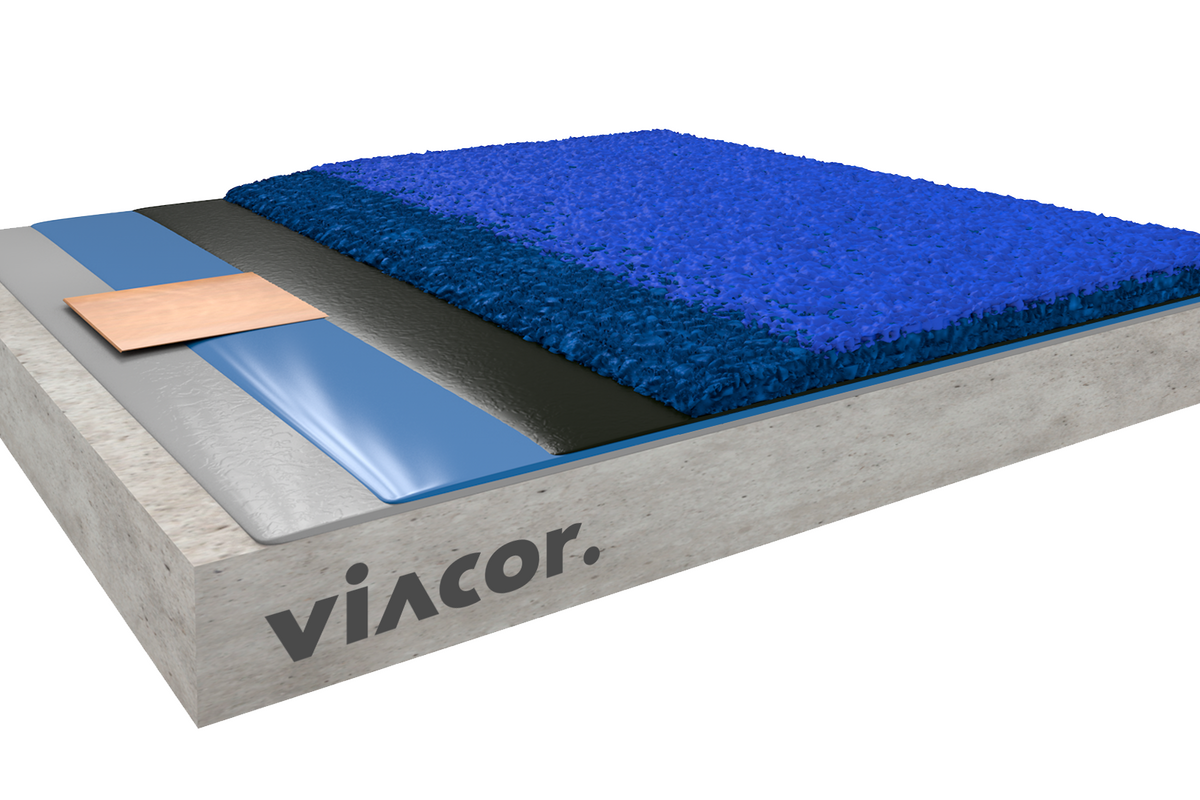

Legal requirements for industrial floors

Various requirements from standards, test regulations and laws determine the basic structure of the floor system. Depending on the location and use, different requirements apply to floor coatings. The suitability of a floor system for these requirements may have to be tested and certified by external testing institutes.