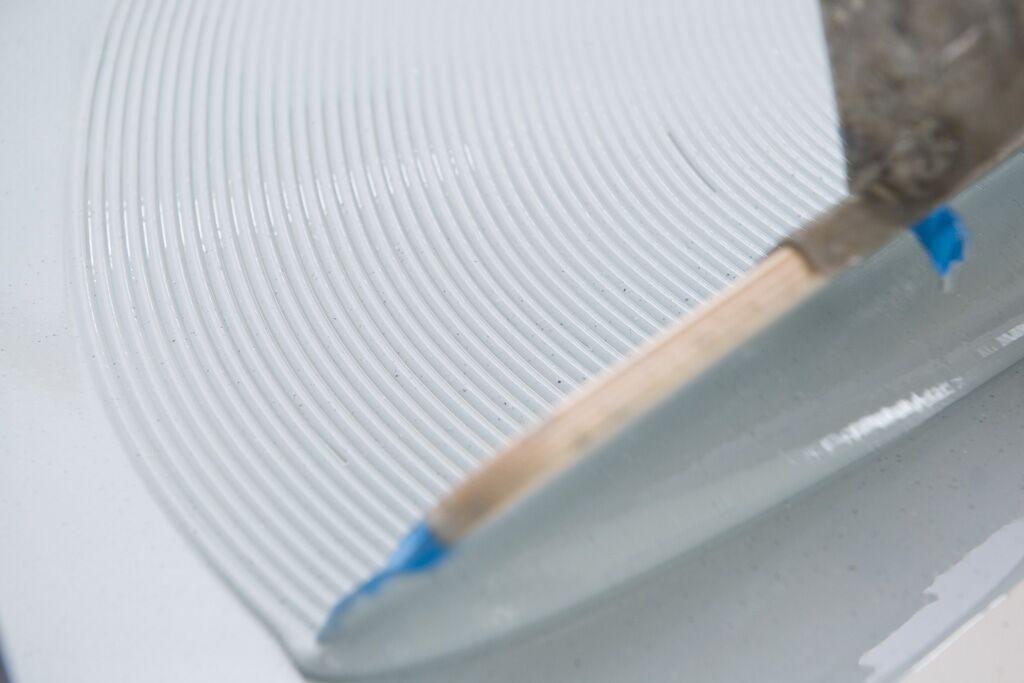

We have special systems that have to be antistatic, non-slip and highly resistant to chemicals, for example. That would be for example the system VIASOL UNIVERSAL HBV voltex SR. Many of our tested VIASOL industrial floor systems made of epoxy resin are equipped with several functions. Here you will find an overview of all industrial flooring systems:

production facilities and Gastro & Healthcare

So that you can find your way around the designations, our nomenclature in brief:

GREEN LINE ECO = Low emissions (tested

EXPRESS = Rapidly processable and rapid-hardening systems Fast-hardening industrial floor systems

SR = slip resistant

HBV = Chemically highly resistant systems suitable for HBV plants (manufacture, treat, use)

WHG = Chemically highly resistant systems according to the Water Resources Act for LAU systems (storage, filling, handling)

voltex & conductive = Electrically (dissipative) conductive coating systems

ESD = Electrically conductive with increased requirements for ESD protection

M / spray (Systems) = Manual processing / mechanical (spray) processing

QCV = Dyed Color Quartz Sand (colored)

QNV = Natural quartz sand (in many colors)

UV = UV-stable

resist = Particularly wear-resistant system

aio = all in one – System built up with only one product

(UREA) HYBRID = Material combination of polyurea and polyurethane

soft = Particularly impact sound-insulating system using a liquid elastic layer

comfort = Particularly impact sound-insulating system using a foam mat

SKY = Products/systems with 3D effect fillers for a special appearance