- News

- Parking

- EP floor coating

Almost every processor of epoxy resin-based floor coatings has experienced this undesirable phenomenon at first hand.

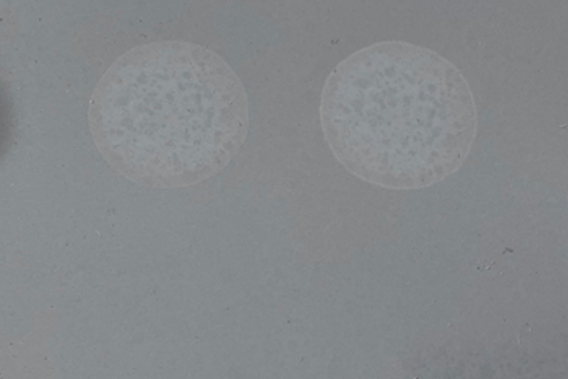

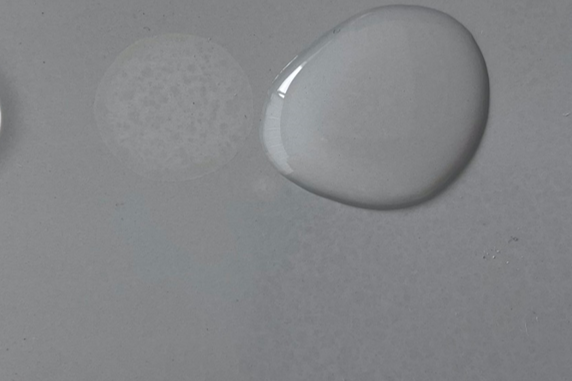

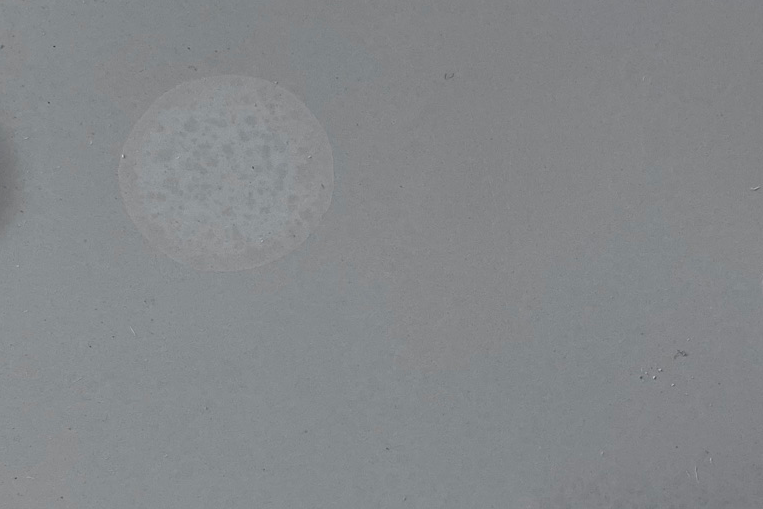

During the curing process, unattractive white discolorations appear in spots or even over large areas on an applied coating. The discolorations, which are visually reminiscent of water stains or lime deposits, but in contrast cannot simply be rinsed off, cause discontent among processors and builders, especially in the final sealing layer.

The resulting whitish substance is known by the term carbamate. In the cooler seasons of autumn and spring, when synthetic resin floor coatings are still being applied, for example in parking garages and underground garages, the risk of unwanted carbamate formation on construction sites is increased. An understanding of its causes and possible countermeasures is therefore particularly important.